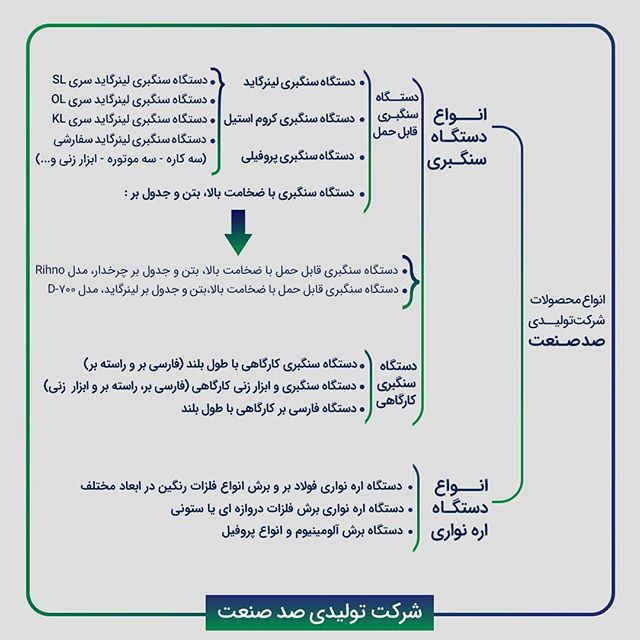

List of SadSanat stone cutting machines

SadSanat Portable Stone Cutting Machine – Linear Guide Series

SadSanat Portable Stone Cutting Machine – Unique and Turbo Plus Series

Portable Stone Cutting Machine – Omega Linear Guide Series

Sad Sanat Industrial Stone Cutting Machine

Curb Stone Cutting Machine RHINO-700 by SadSanat

Portable Stone Cutting Machine – Chrome Steel by SadSanat

To learn more about the different types of stone cutting machines by SadSanat, you can visit the SadSanat channel on Aparat.

Introduction of SadSanat Company

SadSanat Manufacturing Company is the first producer of stone cutting machines in Iran. SadSanat stone cutting machines feature the latest global technologies in the field of stone cutting and have valid certifications from Europe.

SadSanat Company, throughout its years of operation, has produced various types of stone cutting machines in Iran based on customer needs.

SadSanat Construction Stone Cutting Machines

SadSanat construction stone cutting machines each have their own unique features. On this page, we will introduce you to all the stone cutting machines by SadSanat.

This page is a comprehensive guide to all the stone cutting machines of SadSanat Company. You can use the links on this page to visit each section and find more specialized information.

What is a stone cutting machine?

A stone cutting machine is a device capable of cutting various types of stone, tile, and ceramic in different sizes and shapes. Stone cutting machines can be either portable or stationary.

For many years, numerous devices and tools have been used for cutting or shaping various types of stone.

Advancements in technology in stone cutting machines.

In the past few decades, with the rapid growth of the industry and the adoption of new technologies, highly professional stone cutting machines have been developed.

These machines have made it possible to cut various types of stone and building materials easily, with minimal effort and cost.

Travertine Stone Cutting Machine

It is worth mentioning that today, travertine stone is one of the most widely used and sought-after stones in the market.

SadSanat Manufacturing Company, with the design and production of travertine stone cutting machines, has met the extensive needs of users.

The Role of Stone in the Construction Industry

Today, in the construction industry (especially in our beloved country, Iran), stone holds a very special place. Of course, when we talk about stone, this also includes various types of ceramics and tiles.

Iran is considered one of the richest sources of various mineral stones in the world. Due to the abundance of different types of stones, the use of stone in different industries in Iran is thriving.

Various types of stones are used throughout construction. This usage is not limited to buildings alone, and in different sectors of the industry, the traces of their use can be found almost everywhere.

The necessity of cutting stone into appropriate sizes

In order to use various types of stone in different parts of construction, the stone must first be cut into appropriate sizes and pieces for installation in different sections.

You may want to use stone for the flooring, or perhaps for the walls or facade of a building. You might also need to use stone in various sections to implement your decoration.

For this reason, you will undoubtedly need to cut different kinds of stone into various pieces, sizes, dimensions, and shapes to fit them into the necessary locations.

This is where the stone cutting machine for facades will come to your aid, allowing you to cut building materials into any desired shape and size.

You can use this machine to cut types of stone in different sizes and thicknesses. Additionally, you can cut ceramics, tiles, bricks, or blocks as well.

Other applications of the stone cutting machine include miter cutting, profiling, and straight cutting in various sizes and dimensions.

SadSanat Company, for many years, has been producing various stone cutting machines, including portable stone cutting machines as well as Industrial stone cutting machines.

The portable models of SadSanat stone cutting machines are produced in weights and sizes that allow for easy transportation. This makes it possible to move these machines without the need for a crane or forklift.

The Industrial models produced by SadSanat are built with larger dimensions. As a result, these machines have wide applications in industrial projects. Due to the size of the stone cutting machines, it is possible to cut larger stones in straight lines. Additionally, they can be used for miter cutting or profiling with larger dimensions.

The types of portable stone cutting machines produced by SadSanat include the following:

- Linear Guide Stone Cutting Machine

- Chrome Steel Stone Cutting Machine

- Profile Stone Cutting Machines

- Thick Slab Stone Cutting Machine, Concrete Cutter, Curb Stone Cutter, Brick Cutter

The types of Industrial stone cutting machines produced by SadSanat include the following:

- Slab Stone Cutting Machine (45 digree miter cutting and Straight Cutting)

- Industrial Stone Cutting and Profiling Machine (Miter Cut, Straight Cut, and Edge Profiling)

- Industrial Slab Stone Miter Cutting Machine

As the name suggests, Sad Sanat’s portable stone cutting machines are designed to be easily transported and moved.

These types of machines are used for cutting various types of building and decorative stones for building facades. With this portable stone cutting machine, you can make cuts in various sizes (including straight cuts or miter cuts at a 45-degree angle).

These machines generally have a worktable, and you can easily move them between different floors of a project or across various projects.

The single-phase motor installed in this series of machines places them in the single-phase stone cutting machine category of Sad Sanat.

Considering the needs of customers in this field, Sad Sanat Company has produced a wide range of portable stone cutting machines for worldwide market.

Each portable stone cutting machine has unique specifications that vary depending on the type.

Some of the most well-known models of these stone cutting machines include: Sad Sanat, Omega, Kavosh, and Rhino.

Specifications and Advantages of Sad Sanat Stone Cutting Machines

- Excellent after-sales service and reliable warranty for the stone cutting machine.

- Completely domestic production (the political and economic conditions of the country have no impact on the production of this machine).

- High-quality materials and professional-grade components used in the construction of various stone cutting machines.

- The movement method of the stone cutting machine head for cutting various types of stone.

- Ease of use and convenience in operating these machines.

- High cutting precision of Sad Sanat stone cutting machines.

- Suitable dimensions of the stone cutting machine.

- Cutting length of the stone cutting machine.

- Ability to operate with a single-phase or three-phase motor (by default, these machines are produced with a single-phase motor).

Wide applications of portable stone cutting machines.

In practice, these stone cutting machines can be used to cut various types of stone, concrete, curbs, blocks, and bricks. The main advantage of this series of Sad Sanat machines is their very easy portability and minimal effort required for relocation.

Due to the size and dimensions of these stone cutting machines, their use is not limited to a specific location or project. Therefore, you can easily use these machines at any site or project.

Keep in mind that moving large stones or heavy materials is certainly more difficult than relocating a stone cutting machine. Therefore, you can easily transport the stone cutting machine to different locations and use it in various projects.

This feature allows you to save significantly both in terms of cost and time across different projects.

In this section, we will introduce the various types of stone cutting machines by Sad Sanat.

As previously mentioned, Sad Sanat offers a variety of portable stone cutting machines that can be used for different applications.

Sad Sanat Linear Guide Stone Cutting Machine.

One of the categories of stone cutting machines produced by Sad Sanat is the Linear Guide Stone Cutting Machine.

The Linear Guide Stone Cutting Machine features a movement rail on which the head of the machine can move. Typically, this head movement occurs on two linear rails, moving forward and backward.

In different models of the Linear Guide stone cutting machines from Sadsanat, you can replace the manual handle with a semi-automatic gearbox for moving the head back and forth on the rail. This makes the stone cutting process easier and ensures higher precision.

The Linear Guide stone cutting machines made by Sadsanat generally operate on single-phase electricity, but all of them are also capable of being switched to a three-phase motor.

Linear Guide machines can be used for cutting various decorative building stones, including stones such as travertine, granite, ceramic, marble, and tiles.

One of the biggest advantages of the Linear Guide machines by Sadsanat is their customization capability, which can initially be requested by the customer from our team.

Applications of the Linear Guide Stone Cutting Machine

Due to having three sizes for effective cutting length, the Linear Guide stone cutting machines are widely used in stonework and facade construction projects. These machines can also be used for straight cutting and miter cutting of various stones, tiles, and ceramics.

Generally, in projects where long stone lengths are required and the margin of error must be close to zero, the Linear Guide stone cutting machines are the best choice.

The Linear Guide series stone cutting machines are widely used in cutting various decorative stones in the construction industry. They are used for cutting various stones such as travertine, marble, granite, ceramic, and tiles.

The stone cutting machines with Linear Guide are divided into four categories. These categories are:

- The SL series Linear Guide Machine

- OL Series Linear Guide Machine

- KL Series Linear Guide Machine

- Custom Linear Guide Machine

Next, we will explain these machines and how they operate.

1- Linearguide Stone Cutting Machine, Sade Sanat Model, Series SL

The SL series machines from the Linearguide category of stone cutting machines are highly precise and widely used portable stone cutting machines by Sade Sanat.

The useful cutting length in this series of machines is available in three sizes: 150, 200, and 260. However, you can cut custom dimensions up to the maximum cutting length of the machine with very high precision. For example, for the 200 model, you can easily and precisely cut any size up to 200 in length.

One of the advantages of this series is the placement of the stone cutting disc head on rails made of alloy steel. This setup ensures smooth movement during the cutting process, allowing the cutting operation to be performed easily and effectively.

The SL series of linear guide stone cutting machines, known by the model name “Sadsanat,” are recognized in the market.

2- Omega Series OL Linear Guide Stone Cutting Machine Model

This series of linear guide stone cutting machines has differences compared to the SL series:

- In this series, the machine frame and its base are reinforced.

- The rail of the Linerguide stone cutting machine, which carries the cutting head for stone cutting, has also been reinforced and improved for better performance.

- In the SL series, you can request the installation of a manual gearbox from Sadsanat and customize the device. However, in the OL series, the manual gearbox is already installed on the device from the beginning.

- The weight of the Omega device is slightly higher than the SL device due to minor aesthetic changes.

These stone cutting machines, known as the Omega model, are recognized in the market.

Customization of Sadsanat machines.

Due to the vastness of the construction industry and the flexibility given to designers and builders in this field, in many cases, stone cutting with specific configurations is required in buildings.

For this reason, Sadsanat company decided, from the very beginning of manufacturing its stone cutting machines, to provide the option of customizing various stone cutting machines for its customers.

Due to the low error margin of these machines, it is possible for you to customize various parts of them for your specific needs.

The steps to order a custom Linear Guide machine

To order a customized machine, you must first contact Sad Sanat Company and submit your request to our engineering team. Initially, the engineering team needs to assess whether the machine can be manufactured or not.

Certainly! Here’s a refined version:

If the customization feasibility is confirmed, the customer will be provided with a cost estimate. Following this, the prototyping process will commence, and once the necessary quantity is achieved, the machine will move into full-scale production.

Custom devices are typically offered on the Linear Guide machines as well.

To place an order for the production and customization of a device based on your needs, you can contact Sadsanat Company.

3- Kavosh Series K Chrome Steel Stone Cutting Machine

4o mini

Another stone cutting machine from Sadsanat is the Chrome Steel Shaft Cutting Machine, known as the Kavosh Series in the market.

The main difference between this series and the Linerguide series is the shaft on which the machine head moves. In this series, the cutting disc head moves along a chrome steel shaft.

The primary advantage of this machine over the Linerguide stone cutting series lies in its wide range of sizes and its more affordable price. The chrome steel shaft model Kavosh offers a broad selection of cutting dimensions, making it highly versatile. Moreover, it is a more cost-effective option compared to the Linerguide series, without compromising on quality.

Another advantage of this stone cutting machine is the adjustable head height, which can be easily modified to suit different cutting needs.

However, it should be noted that the error margin in chromium steel stone cutting machines is higher compared to the Linerguide series cutting machines.

The applications of chromium steel stone cutting machines

Due to the ease of hand movement during stone cutting and the ability to maneuver the hand with it, this machine is highly useful in areas where cutting various types of decorative stones for buildings is required.

The chrome steel shaft cutting machine can be used for cutting various types of stone, especially marble, tiles, ceramics, and travertine.

The Kavosh 65 chrome steel cutting machine, which falls under the category of portable cutting machines, is also known as a small cutting machine due to its different dimensions. Its notable efficiency in construction projects comes from its ease of transport and mobility.

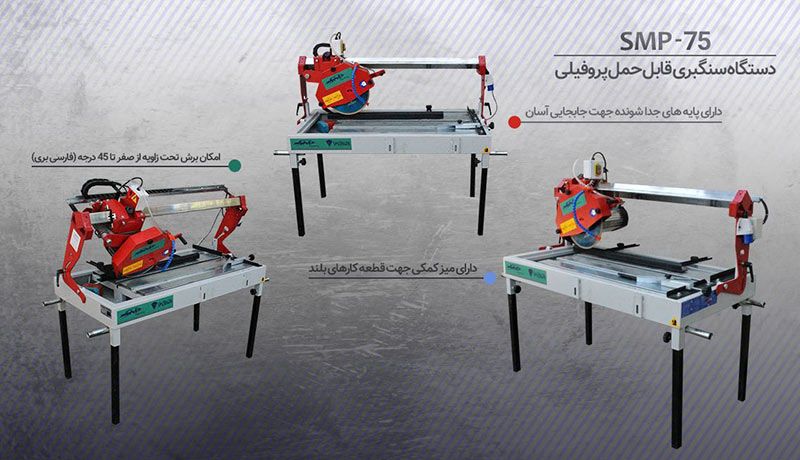

4- Sad Sanat Profile Cutting Machine

The profile cutting machine is very similar in functionality to other models of portable stone cutting machines.

The key difference with this machine is the material of the rail on which the machine’s head is mounted. In this model, the cutting disk head is mounted on a profile rail.

This model is also known in the market as the Profile Stone Cutter SMP Series.

This machine is capable of cutting stones with lengths of 75 and 140 centimeters, and it is used for cutting stones with shorter lengths.

The head of this machine, like other series, has the ability to adjust the height. Additionally, the head can be angled up to 45 degrees, which allows stoneworkers to use this series for miter cuts as well.

Applications of Sad Sanat Profile Stone Cutter

Due to the limitation in the effective cutting length of these machines, they are practically used for cutting stones into shorter lengths.

5- Sad Sanat Heavy Duty Stone Cutter, Concrete Cutter, and Curb Cutter.

As the name of this series suggests, these stone cutting machines by Sad Sanat are specifically designed to handle cutting various types of thick stone with precision and efficiency.

These stone cutting machines are fully capable of handling a wide range of cuts on thick materials such as curbstone, concrete, blocks, and bricks.

In this series of stone cutting machines, Sad Sanat has developed two distinct models. One model is equipped with wheels for enhanced mobility, while the other comes with a sturdy base, similar to the Linearguide series.

The following introduces these two models of high-thickness stone cutting machines in detail:

Sad Sanat Curb Stone Cutting Machine – Rhino Model

Another advanced stone cutting machine developed by Sad Sanat is the Rhino model, specifically designed for cutting various types of curbstones. This model falls under Sad Sanat’s category of specialized-use stone cutting machines.

This machine is equipped with wheels to enable chassis mobility. It can be mounted on either three or four wheels, depending on operational needs.

The intended use of the curb stone cutting machine differs from the other models introduced on this page. This machine is specifically designed for cutting high-thickness materials such as curbstone, concrete, blocks, and bricks.

The Rhino model high-thickness stone cutting machine generally features larger blades for stone cutting. This machine is capable of easily performing stone cutting tasks at various angles.

It is important to note that this stone cutting machine operates exclusively with a three-phase motor.

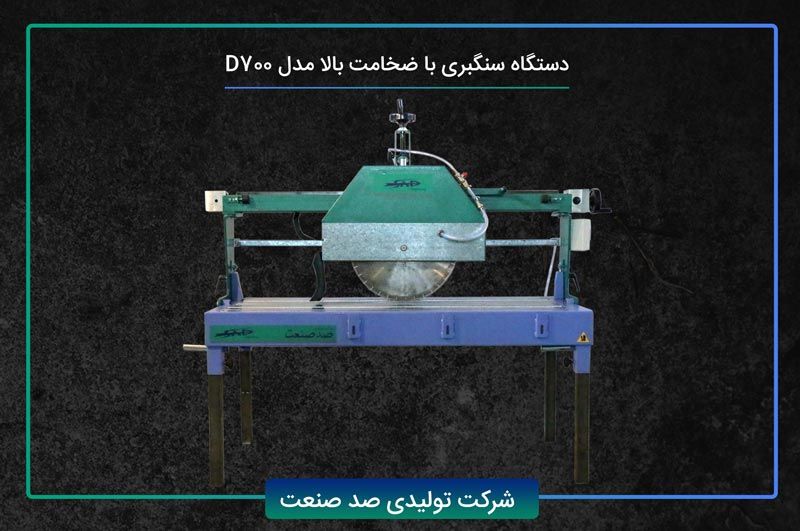

High-Thickness Stone Cutting Machine – D-700 Model

Similar to the Rhino model, this D-700 stone cutting machine is capable of cutting high-thickness stones. It is used for cutting various thick materials such as concrete and curbstones.

The main difference between this model and the Rhino model is the movement of the cutting head on Linear Guide rails, a feature not present in the Rhino model.

In the Rhino stone cutting machine, the cutting head and blade are fixed, and instead, the worktable moves. However, in the D-700 model, the cutting head is movable and can move forward and backward.

Another difference of this machine is the variety in cutting length compared to the Rhino series.

Similar to the machines in the Linearguide series, this stone cutting machine is mounted on a chassis. The cutting head is also mounted on 20 Linear Guide rails.

This machine operates with a three-phase motor, which is necessary to provide the power required for more precise and higher-quality cutting.

Even the motor of this machine is different from the motors used in other products manufactured by Sad Sanat.

In addition, this machine is capable of cutting at various angles. For even greater precision in cutting, a semi-automatic gearbox can also be installed on it.

In recent years, Sad Sanat Manufacturing Company has expanded the variety of its stone cutting machines, taking into account the conditions and needs of the Iranian market as well as its customers.

Given that a large number of stone vendors and stonemasons operate in workshop and factory environments, there has always been a consistent demand for workshop-based stone cutting machines in the market.

Considering this need, Sad Sanat has taken steps to produce various workshop stone cutting machines as well as stone profiling machines.

Sad Sanat workshop stone cutting machines are divided into three models:

- Omega Platinum Industrial Stone Cutting and Profiling Machine

- Titanium Slab Stone Cutting Machine

- Industrial Slab Stone Miter Cutting Machine

It is worth mentioning that all the aforementioned industrial machines fall under the category of Sad Sanat’s automatic stone cutting machines.

Additionally, the Titanium stone cutting machine and Sad Sanat miter cutting machine are also used for cutting decorative and precious stones, and they are often referred to as decorative stone cutting machines.

In this section, we will provide a brief introduction to industrial stone cutting and profiling machines, as well as familiarize ourselves with the various models produced by Sad Sanat.

If you require more detailed technical information about each of these machines, you can click on the full specifications of each product to visit its product page on the Sad Sanat website:

Omega Platinum Industrial Stone Cutting and Profiling Machine Model

This stone cutting machine is one of the highly versatile machines produced by Sad Sanat. The Omega Platinum model is used for cutting various types of stones with different lengths and widths.

It is worth noting that the effective cutting length of this machine is 2 meters.

This machine is also referred to as a stone profiling machine in the market.

Additionally, with this machine, you can perform various profiling tasks on stones. On the other hand, it also provides the capability for miter cutting of stones.

Another feature of this stone cutting machine is its PLC board, which is fully programmable and controllable.

On the other hand, this machine is also inverter-compatible. The inverter feature allows the machine to operate with higher power while consuming less electricity.

Due to its profiling function, the design of this stone cutting machine for Roman facade stones is somewhat unique. The cutting head is adjustable in height along the Y-axis, while the disk head remains fixed along the horizontal axis.

In this series, the worktable moves smoothly to the left and right, ensuring efficient stone cutting.

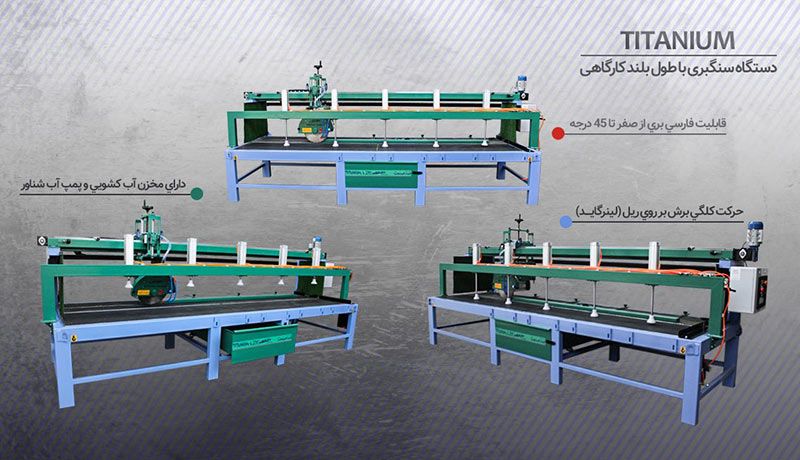

Sad Sanat Titanium Industrial Slab Stone Cutting Machine

Another stone cutting machine produced by Sad Sanat is the Titanium model. Like other machines in the industrial series, this machine is capable of cutting various types of slab stones.

With this machine, you can cut stones up to 3 meters and 30 centimeters in length.

Like the Omega Platinum series, this machine is equipped with a three-phase inverter motor, which allows it to operate with greater power while consuming less electricity.

Another feature of this machine is its PLC board and the motor’s programmability, allowing for precise control.

The Titanium model industrial stone cutting machine not only offers straight cutting but also provides miter cutting capabilities for Slabs.

The key feature of this series is its high-precision miter cutting capability. For this reason, it is widely used for cutting decorative stones, where precision is crucial.

Another feature of this model is the installation of an automatic gearbox for the movement of the cutting head. The automatic gearbox eliminates the need for manual assistance when moving the cutting head on this machine.

This machine can be customized according to the customer’s needs. Therefore, depending on your requirements, you can modify the machine and add various features to it.

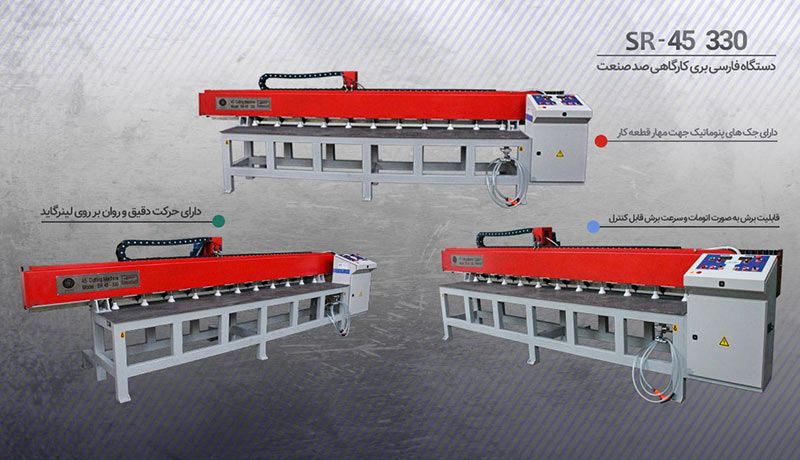

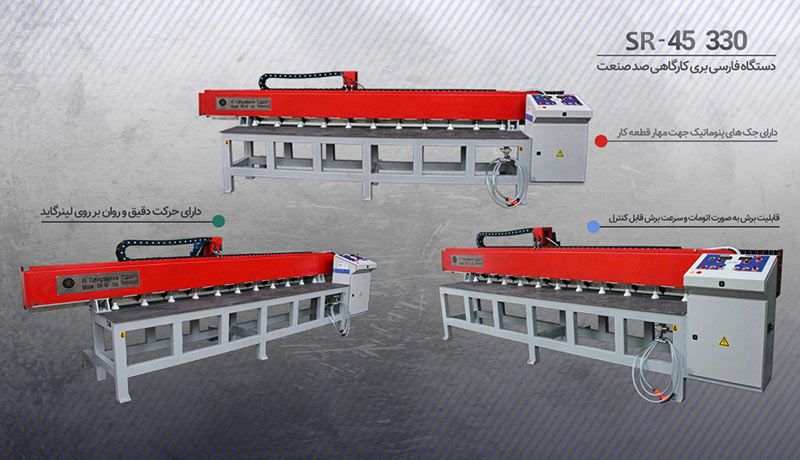

Sad Sanat Slab Stone Miter Cutting Machine (Model SR-45)

Another stone cutting machine produced by Sad Sanat in the industrial category is the long-length miter cutting machine. This industrial miter cutting machine is known in the market by the brand name SR-45.

Another stone cutting machine produced by Sad Sanat in the industrial category is the slab miter cutting machine. This industrial miter cutting machine is known in the market by the brand name SR-45.

Like other Sad Sanat industrial stone cutting machines, this device operates with a three-phase inverter motor.

These stone cutting machines are equipped with pneumatic jacks that securely hold the stone in place during the miter cutting process.

Another notable feature of this stone cutting machine is its construction technology, which is built according to the latest global standards and methods.

The price of a stone cutting machine depends on various factors and can vary based on the machine’s application and features. Manual and portable stone cutting machines, which are used for small projects and construction, generally have a lower price. In contrast, industrial and workshop models that feature advanced systems such as automatic cutting, water cooling, and high precision cutting tend to be more expensive. The brand of the machine also has a significant impact on the price; reputable and high-quality brands typically have a higher price but offer better durability and precision, leading to cost savings in the long run. Additionally, factors such as blade size, motor power, adjustable cutting angles, and additional features like precise rulers and dust extraction systems also influence the machine’s price. To purchase the right stone cutting machine, it’s best to identify your work requirements, cutting volume, and precision needs, and then compare different options based on price and quality.